Straight

Talking Classic American issue 180 |

||

When

we left you last time, we did so with talk of alignment and terms such

as ‘toe in’ and ‘toe out’ whizzing through your

head. We also mentioned that your steering alignment could not be correctly

set-up if there were any damaged or worn parts within the system. This

time we want to look a little deeper in to the problems of worn steering

components and also delve further in to the subject of steering geometry,

this time looking at ‘caster’ and ‘camber’.

Before you ask, NO, these are not star constellations and we do not

need to seek the help of Patrick Moore to understand them. These are,

however, critical and often little understood measurements within our

steering geometry set-up. If your caster and camber angles are not set

correctly, all manner of problems can occur. These include the vehicle

pulling to one side, excessive tyre wear and wheel alignment problems.

So if you have a problem with you car wandering, and we don’t

mean it trying to chat up the car next door, or if you find the steering

just doesn’t feel right then read on we may have the cure. So to start let’s ask the following question: What items that are likely to wear out in our steering system? The simplest answer to this is anything that moves. However, this may seem a little vague. To clarify things it may be better to say any component that has a moving part. So, ball joints for example, or any steering component that has a ball type joint as part of its construction could be classed as wearable. However, components such as drag links that simply have holes in them to take the ball joints of other component parts are normally classed as a non-wear items. On older vehicles that have kingpin set-ups, the kingpins themselves are also a wearable item and should be checked regularly. Modern innovations such as grease points, see fig 1, on steering joints and ball joints have allowed us, to a certain degree, to extend the longevity your steering components. Of course you actually have to make the effort to make greasing these joints part of your regular vehicle servicing, A in fig 2. You do of course need to use a good quality, high temperature grease. So the joints you should make part of a regular check are upper and lower ball joints and inner and outer track rod ends. On top of these also check any joints you may have in the pitman arm, idler arm and centre or drag link. As we always try to point out, spending a little time performing these regular checks now can save you a lot of time and money later. |

||

Fig 1. |

Fig 2. |

|

|

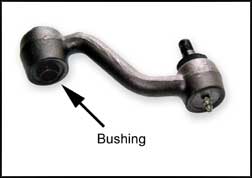

If we look at the idler arms from older vehicles,

some of these may have a bushing where the two halves of the idler arm

join, see fig 3. This bushing can also wear causing

steering alignment problems. Therefore this bush should be made part

of your regular check. You should be aware that a lot of steering component

manufacturers are no longer making the replacement bushes for this type

of idler arm. The good news, however, is that most of these companies

are now making upgraded replacement idler arms for certain applications.

This is something you may want to check, with your parts supplier, if

you feel your idler bush needs attention. Replacing your current idler

arm with a new assembly, which is serviceable, will again save you time

and money later.

With all this talk of worn joints and bushes it is easy to forget that sometimes it is the smallest and simplest of things that cause the largest problems. You may of noticed, whilst checking your steering components, small rubber dust covers, or boots, on most of the ball type joints, see fig 4. BIG DEAL we hear most of you saying, however, most people underestimate the importance of our little rubber friends. If these are split or damaged in any way they will allow moisture in to the joint. This could be from rain, off the road or simply condensation it doesn’t really matter, once water has entered the joint the problems have already begun. |

||

Fig 3. |

Fig 4. |

|

Obviously

corrosion is the biggest issue, especially if the vehicle is not used

on a regular basis. Once the corrosion has set in then the joint can

be considered unrepairable and should be replaced. Whilst there are

some parts people out there supplying replacement boots, we feel that

once you have discovered a damaged boot, damage to he joint itself may

have already occurred. The boots shown in fig 5 have

been neglected for some time, allowing dirt and moisture to do its job

and ruin the joints. So to save false economy we recommend replacing

the joint as a whole. Whilst this may be a little more expensive initially

it will potentially save on problems later on.

As a parallel to this

dust boot problem, those of you with a rack system should regularly

check the condition of the rubber gaiters that protect the ends of the

steering rack. Again if these are damaged in anyway they can allow moisture

to enter the end of the rack, causing all manner of problems. If you

find you have any splits or tears in the gaiter you should have the

rack checked for damage. Any problems usually result from moisture entering

and corroding the rack tube or dirt and grit entering the tube and causing

damage to the rack seals. If everything is given a clean bill of health

then just replace the gaiters, see fig 6. Worse case

scenario is that you may have to replace the entire rack, however, damage

is usually confined to the inner track rods. |

||

Fig 5. |

Fig 6. |

|

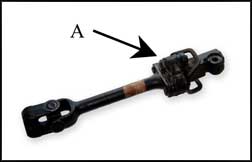

Moving

away from ball joints, gaiters and boots we are going to take a look

at one of the most important and yet one of the most neglected components

in the steering system, the steering coupling. This is, on most vehicles,

either a reinforced rubber block, shown as A in fig 7,

or a reinforced rubber disc that fits between the end of the steering

column and the top of the steering box or rack, see fig 8. A

lot of vehicle manufacturers have replaced the rubber component on more

modern applications with a universal joint set-up. Because of the amount

of stress this item is under, it should be checked regularly, especially

if you have the rubber type coupling. |

||

Fig 7 |

Fig 8 |

|

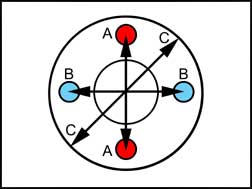

Because

this coupling plays such an important role in the steering system, if

you see any signs of damage such as the disc becoming oil soaked and

soft or split the coupling should be replaced immediately, see fig

9. Unfortunately one size does not fit all, and when you call

your parts supplier for a replacement you may find that they require

some measurements from the old coupling, especially if it is the disc

type. Firstly, they will probably ask for an overall diameter of the

disc, measurement 'C' in fig 10. Secondly they will

need the measurements between the bolt hole centres. These are shown

as measurements 'A' red to red and 'B' blue to blue in fig 10.

Armed with this information your supplier should have no trouble providing

the correct disc. |

||

Fig 9 |

Fig 10 |

|

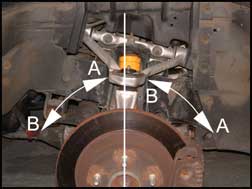

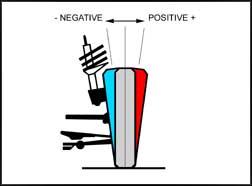

As

we move through our steering system it is time to become familiar with

some new terms. We did mention these at the beginning of this article,

the caster and the camber, and no these are not cooking ingredients

or rivers. To begin with let’s see if we can get a basic understanding

of each term and the problems we can expect to see if we are having

trouble with either the caster or camber angles. Let us start with the

caster. As mentioned last time, when you steer your vehicle the front

wheels turn on pivot points attached to the vehicle's suspension. On

modern vehicles this is usually a ball joint set-up, and on earlier

vehicles kingpins. The caster angle is measured in degrees and is the

amount that the upper pivot points lean towards the front or rear of

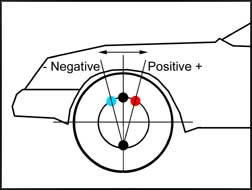

the vehicle when viewed from the side, see fig 11.

The caster if often referred to as being positive when the top of the

pivot is leaning toward the rear of the vehicle, toward A in fig

11 or towards the red in fig 12. It is said

to be negative when the top of the pivot is leaning toward the front

of the vehicle, B in fig 11 or towards the blue in

fig 12. |

||

Fig 11 |

Fig 12 |

|

If

your caster is out of adjustment then you are likely to suffer problems

when you try to have the vehicles wheel alignment or tracking done.

For example if the caster angle is different on each side of the vehicle

it will tend to pull to the side with the less positive caster angle.

If you find that your vehicle has extremely light steering, wants to

wander and is difficult to keep in a straight line, then it is possible

that the caster, whilst equal on both sides of the vehicle, maybe too

negative. Almost the opposite can be said if the caster angle is too

positive. The steering will be very heavy and may be likely to kick

at the slightest bump. |

||

Fig 13 |

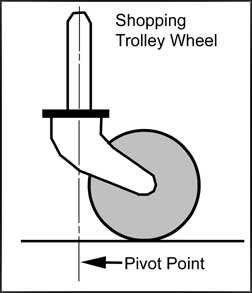

IProbably

the easiest way to understand the caster angle is to look at the wheels

on a shopping trolley, see fig 13. Whilst the pivot

point of the trolley wheel is not at an angle its line does intersect

the ground ahead of the contact area of the wheel. Whilst the wheel

is behind the pivot where its line contacts the ground it is said to

have positive caster. Now try to imagine pushing this trolley and keep

the wheel ahead of the pivot point. The wheel will constantly try to

rotate to being behind the pivot point. This is also what happens on

a car or truck when the caster angle is set too far negative. It is

this that can cause problems with wheel alignment. It should be noted

that on many front wheel drive vehicles the caster angle cannot be adjusted.

So if there is a problem with caster here, it is more likely that something

is worn or damaged and will either require repair or replacement. It

should also be noted that any problems with the caster angle have very

little affect on tyre wear. |

|

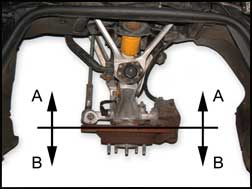

Now

let us turn our attention to the subject of the camber angle. This angle

is also measured in degrees. It is the amount the wheels lean in or

out from the vehicle when viewed from the front or rear. For example

if the top of the wheel is leaning away from the centre line of the

vehicle, towards B in fig 14 and towards the red in

fig 15, this is said to be a positive camber angle.

However, if the top of the wheel is leaning towards the centre line

of the vehicle, towards the A in fig 14 and towards

the blue in fig 15, we have what is known as a negative

camber angle. |

||

Fig 14 |

Fig 15 |

|

Unlike

the caster angle, if the camber angle is out of adjustment then this

will have a detrimental affect on tyre wear, see fig 16,

causing a tyre to wear prematurely on one side of the tread. So if the

vehicles camber angle is set too negative this will cause excessive

tyre wear on the inside edge of the tyre. |

||

Obviously,

if the camber is set too positive the wear will be excessive on the

outside edge of the tread. The vehicle will tend to pull to one side

if the camber angles a set differently on each side of the vehicle.

The pull will be to the side that has the more positive camber. Again

many front wheel drive vehicles have set-ups where the camber angle

cannot be adjusted. If this is the case with your vehicle and you have

a problem with the camber angle, once again check for worn or damaged

parts. On most vehicles both the caster and camber angles are adjusted

using small metal shims, see fig 17. These are of various

thicknesses allowing varying degrees of adjustment. For example, the

camber angle is usually adjusted by adding or removing these small shims

behind the upper control arm, thus allowing the top of the wheel to

move closer or further away from the centre line of the vehicle. |

Fig 16 |

|

Fig 17 |

|

|

There

is one final term, which we have left till last, which is the Steering

Axis Inclination (SAI). This is a measurement in degrees that forms

part of the calculated, but not measurable, camber angle. This is not

adjustable but instead is actually part of the fixed design of the vehicle.

It should be noted that SAI is usually referred to as kingpin inclination

on older cars and trucks that use kingpins instead of ball joints. It

is the SAI that causes the front of the vehicle to lift slightly when

you turn the wheels away from the ahead position. Because of this the

weight of the vehicle causes the wheels to centre themselves, if you

release the steering wheel after you make a turn. Again if the SAI is

different from side to side on the vehicle it can cause the vehicle

to pull to one side at slow speeds. Because the SAI is not adjustable

the only way it can be incorrect is due to damaged or worn parts. These

would obviously have to be repaired or replaced to correct the problem.

Some wheel alignment machines are able to diagnose if a vehicles problem

lies with the SAI or the camber angle. If you suspect a problem with

the SAI, then finding a wheel alignment company with this type of machine

has obvious benefits. |

||

So

what have we learnt here? Nothing we hear you say! Well if nothing else

we hope you know that it is worth checking out our steering components

on a regular basis, and where appropriate treating them to a good greasing.

As we have tried to point out on many occasions, prevention is always

better than cure. It’s usually cheaper too. If you are experiencing

problems with your steering, such as a pull to one side, vibrations

or knocking. Try getting the steering alignment checked out, if this

makes very little or no difference then at least you now know where

to start looking to help solve the problem. Have the caster and camber

angles checked, if they are not adjustable on your vehicle then have

the steering components checked for signs of wear or damage. Hopefully

this will have you up and running in no time or at leased in a straight

line! Please remember that if you do require any of the parts, mentioned

within these articles, as always they can be obtained from Ultimate

Spares of America or any of the other excellent suppliers found within

the pages of this fine publication. |

||