Trouble

at the top |

|

|

|

For those of us lucky

enough to own a convertible, we do not have to preach the virtues

of, fun and frolics to be had with such great cars, well at least

not to each other, just the uninitiated. Convertibles are meant to

be driven and enjoyed, although this would happen mainly during our

all too short but intense summer. Intense because we seem to cram

so much into so few hot months as possible. How many times have you

driven along a country lane with the top down, your favourite band

oozing from multiple speakers, day dreaming about being a film star

on sunset boulevard with a car full of beautiful women and………….sorry,

must remember, don’t type everything your thinking. |

|

Lets

take these individual components and look at the possible maintenance,

failure and cure for most of the convertible top problems. Firstly the

electrical system. As we have said a three-way switch mounted in the

dashboard or centre console see fig 1, operates the

tops motor, this three-way switch will mean a three-wire connection

at the motor assembly see fig 2. |

|

Fig 1. |

Fig 2. |

If

you believe your switch is at fault a simple continuity check, in this

part of the loom, may reveal a failure in the wiring or switch that

could be easily remedied. Breaks in the wiring are easily fixed with

bullet connectors, but for a professional job you should consider replacing

the complete switch to motor wire especially if the wiring is old or

brittle. As we have said before, a little more time spent now, could

save you from having problems in the future. If you possess a multi-meter

the test is very easy using a simple resistance check, if not a twelve-volt

bulb in a holder with two wires will suffice. The test is a simple one

and is carried out as follows. Assuming you have a meter, find the three-wire

connection at the convertible top motor. One wire will be common (earth

wire) and is usually black. Do ensure this is grounded properly, so

many electrical failures are caused by a poor earth. The other two wires

will be from the two positions of the toggle. Probe the connector with

your multi-meter set at around twenty volts fig 3,

one probe on the common the other probe to one of the other wires, fig

4. |

|

Fig 3. |

...  Fig 4. |

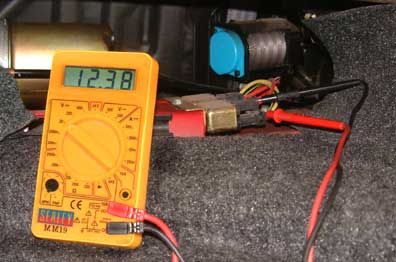

Now

have someone operate the toggle with the ignition on. Try the toggle

in both positions, one position should give a reading of around twelve

volts positive, if you are using the bulb and wire method you bulb should

light up. Now move the probe to the other wire leaving the common in

place. Now with the toggle in the opposite position you should have

a similar reading, this will, however, more than likely be a negative

voltage. The positive voltage driving the motor in one direction and

the negative voltage driving it in the other. If you do not have a reading

at one or both positions you need to check the fuse and as mentioned

earlier the wiring and toggle switch. If you find a blown fuse it would

be prudent to investigate why it has blown. Simply replacing the fuse

without knowing the reason behind its failure can lead to more expensive

problems later on. If you do get a good reading at both positions between

the switch and motor, and you have power to the motor, it would be safe

to say that the fault is elsewhere. As with most electric pumps used

on convertible tops, see fig 5, the most common cause

of failure is age. Because the motor does not get used often enough

to actually wear out, the internal parts usually just physically break

down. Because of the changes in design over the years, it is most unusual

for modern electric motors on American cars to simply fail. The most

age related problems we see are with vehicles dating from the mid seventies

and earlier. Thinking about it this isn’t too bad and says a lot

about the design of the American electric motor, and is a pretty good

track record as we are talking about thirty plus year old electric motors

only just starting to fail. The problem of motor failure can be rectified

in two ways, the most obvious is replacement of the motor, the second

option is refurbishment of the old motor. This service is available

in most parts of the country, a quick scan through the Yellow Pages

and you should find a number of companies offering a rebuild service

for your electric motor. Obviously the replacement of the electric motor

may be advisable if the hydraulic pump also has a problem. This would

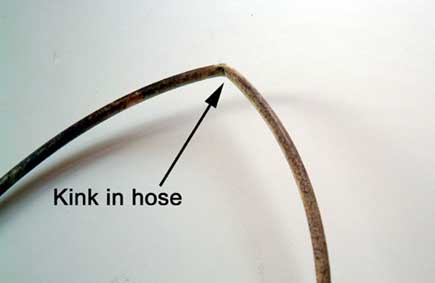

be the most cost-effective way of curing two problems in one go. Moving to the hydraulic hoses, any suspected problems in this area can be checked with a simple visual inspection. The most obvious problem here is leakage. Secondly poor operation can be caused by crushed or kinked hoses fig 6. As always if you find any damage here replace the hoses as necessary. |

|

Fig 5. |

...  Fig 6. |

Unfortunately,

the rams are not so easily diagnosed for problems, but sometimes a visual

inspection of the hoses can reveal a problem within the ram. If you

are fortunate enough to have transparent hoses you may be able to see

air bubbles in the hydraulic fluid when the pump is operated. If this

is the case there is a good chance the ram piston or pump has a problem.

If the seals around the piston are worn they will pass air as well as

fluid. This causes the fluid to become aerated and in turn causes the

top to operate poorly or in extreme cases not at all. Most hydraulic

rams, fig 7, on cars are by the nature of their design

not serviceable, and therefore must be replaced. If your top is working

but possibly not as well as you would like it. It is always worth changing

the fluid, especially on older systems where the fluid will have become

discoloured and contaminated with age. Most convertible top pumps use

automatic transmission fluid, however, some do use brake fluid. So it

is always worth checking your handbook to find out which fluid your

system requires. Using the incorrect fluid or mixing fluids can lead

to hydraulic pump failure. After replacing the fluid always operate

the top a few times, this will bleed the system. Once you have done

this recheck the fluid level at the reservoir and top up as required.

|

|

Fig 7. |

...  Fig 8. |

Having

checked out what we would consider the most obvious problem areas we

move on to what may be thought of regular serviceable parts. It is always

worth checking out the pivot points on the tops mechanism and lubricating

these as necessary fig 8. You should find on most convertibles,

you will be able to make adjustments at these pivot points fig

9. Making minor adjustments will allow for smoother operation

and put less stress on the whole convertible top system. Whilst checking

the pivot points remember to check the rest of the frame structure for

any bent or damaged components. |

|

|

...  Fig 10. |

We

are now entering the final series of checks and with a convertible these

are amongst the more important. It is always worth making a close inspection

of the rubbers that seal the top to the side glass fig 10.

and header rail (front screen) fig 11. These sealing

rubbers are important in not only stopping wind noise and rain from

entering the interior (yes we have all been caught out in the Great

British summer), but also stopping those annoying squeaks and chirps

that can add up an unpleasant drive. |

|

Fig 11. |

..  Fig 12. |

Okay

so we have lubed, adjusted, fixed and possibly replaced components,

now let us turn our attention to caring for the convertible top itself.

There are several do’s and don’ts, most of which are common

sense, you will only ever drop your convertible top and break the glass

rear window once, you will only put the top up or down while driving

and turn it into a parachute once! So as you see common sense goes a

long way to help caring for your top. As we have mentioned earlier,

unless you are a die-hard enthusiast the chances are you will only use

your convertible during our summer months. The all important point here

is storage. If you are going to lay your car up for any length of time,

it is worth considering the following. If it is stored inside always

remember to unlatch the top to take the strain off of the convertible

top material. Try to clean and treat the top before storage. Probably

the most important thing to remember is never store your car with the

top down. This will be detrimental to the material and if you have a

soft rear window the damage caused to this may be irreparable. With

the top folded there is a good chance of having moisture trapped for

long periods, this will lead to mildew and possible staining of the

fabric. The crease marks caused from ‘top down’ storage

can be permanent and in time may turn into splits. With tops that have

a removable headliner, it’s always worth removing and cleaning

this as required. Most removable headliners are simply held in place

with Velcro strips, see fig 12, and or pop fasteners.

Be careful, as there may be some stitching holding it to the hoops.

If the Velcro is not doing it’s job, it is easily replaceable

and will make for a much better fit, this will help you to lose that

‘sagging bag’ look and it will transform your interior.

Do take the time to inspect the attachment of the top material to the

top mechanism and hoops. If the material is starting to part company

with the metal hoops it must be reattached. Now whilst it may be possible

to do this yourself, your local friendly car trimmer will soon have

you and your convertible top reunited in next to no time. A well fitted

top will go a long way to making the roof mechanism operate smoothly. |

|

The

convertible top material must be cared for, regular washing with shampoo

and soft sponge is a good move, and regularly using a special convertible

top cleaner will go a long way to help prolong the life of your top,

and restore the more vibrant original colour fig 13.

Once cleaned properly you should periodically treat the material with

a good quality convertible top proofer, this will not only care for

and protect the material, but will also help to keep the material supple

and prevent the stitching from rotting. If your plastic rear window

makes you feel like you are looking through nicotine stained pub curtains,

there are products available to ‘polish’ some of the discoloration

off. |

|

Fig 13. |

|

If

you have a manually operated top, you can ignore some of what you have

read. Many of you may be thinking that manual tops will be in the domain

of older cars. This couldn’t be more wrong, take for example,

the Corvette, no electric pumps or hydraulic rams to be seen here. The

raising and lowering of the roof is all dealt with using brut force.

This does of course mean that special care and attention should be paid

to the condition of your convertible tops frame structure. As mentioned

earlier damage to this can seriously hamper the tops operation and obviously

even more so with a manually operated roof. Of course a manually operated

top does not change the do’s and don'ts of storage and the care

of the tops material. All this should remain relevant regardless of

how your top is operated.

With the top held in place correctly and adjusted your car will take on a whole new appearance. You will find you have a new found pride in your beloved convertible, and driving it will make you feel that much better. Well, what are you waitin’ for, times a wastin’. Get your ragtop out and make the most of what we like to call……… summer. |

|

|

|